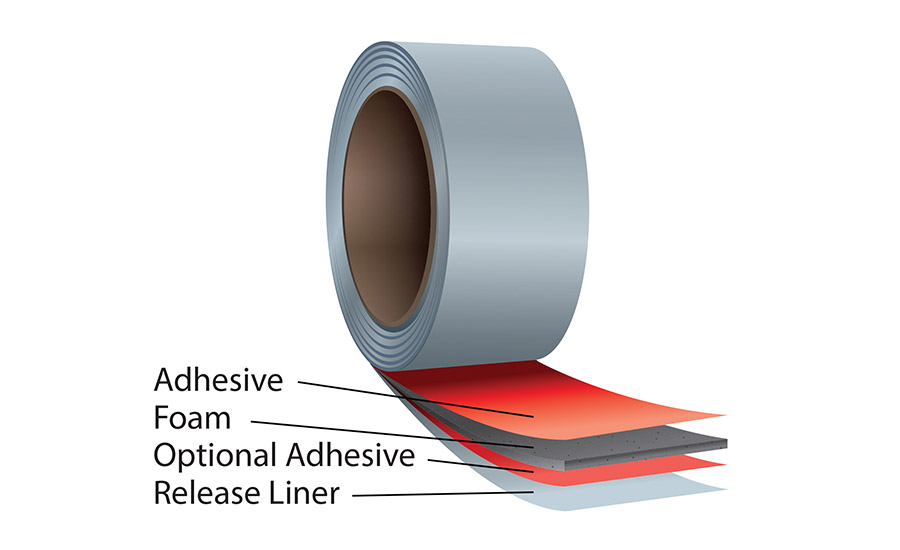

Foam tapes are used in a wide range of markets, such as automotive, packaging, electronics and medical. They serve a number of functions—from vibration dampening to shock absorption to temperature insulation. The end-use application and function of the tape generally guides the overall construction, including the foam and adhesive(s) selected. In general, foam tapes can be either single- or double-coated constructions. In the case of a single-coated tape, the same adhesive must bond to the foam and to the substrate. In double-coated tapes, two different adhesives can be chosen to enhance the anchorage to both the foam and the substrate. Figure 1 depicts the layers of a typical foam tape.

Figure 1. Foam tapes can be either single or double-coated constructions. ©ASI

Crosslinked polyethylene, polyurethane (polyether and polyester), ethylene propylene diene monomer (EPDM), and nitrile-based materials are some of the common foam types used in tape applications. Foam characteristics such as chemistry, surface texture and energy, cellular structure, and density impact adhesive choice. Identifying the optimal adhesive(s) is no easy task, and there is no one-size-fits-all solution that satisfies the needs for all markets, functions, and foam types. A customized approach for each application is required to ensure that the adhesive sufficiently anchors to the foam and meets all critical-to-quality (CTQ) requirements, such as resistance to temperature, UV, and/or solvents.

A variety of pressure-sensitive adhesive (PSA) technologies are available, all of which have their strengths and weaknesses in addressing these CTQ requirements. Table 1 highlights general performance attributes of four main adhesive technologies.